Have you ever returned to your car on a hot summer day to find your navigation system acting sluggishly or your dashboard display flickering? You’re witnessing heat stress in action. Modern vehicles contain more electronic components than ever before, and these sensitive systems face serious challenges from extreme interior temperatures.

Window tinting offers a powerful solution to protect your vehicle’s expensive electronics from heat damage. It’s not just about keeping you comfortable – it’s about preserving the sophisticated technology that makes modern driving possible. Quality window tint can reduce interior temperatures by 15-20 degrees, creating a safer operating environment for delicate electronic components.

Understanding how heat affects vehicle electronics and how window tinting provides protection helps you make informed decisions about protecting your automotive investment. The cost of replacing damaged electronic systems far exceeds the investment in quality window tinting that prevents the damage in the first place.

Understanding Heat Stress in Modern Vehicle Electronics

Today’s vehicles contain dozens of electronic systems that all generate and are affected by heat. From simple radio systems to complex autonomous driving features, every electronic component has temperature limits that affect performance and longevity.

The Science of Electronic Heat Damage

Electronic components operate through precisely controlled electrical currents and chemical reactions. Heat disrupts these processes in multiple ways, causing both immediate performance issues and long-term degradation.

At the molecular level, heat increases the random motion of electrons and ions within electronic components. This increased motion creates electrical noise, reduces efficiency, and can cause components to operate outside their designed parameters.

Heat also accelerates chemical reactions that cause materials to break down over time. Capacitors dry out faster, solder joints become brittle, and plastic housings become warped or cracked. These changes accumulate over time, eventually leading to system failures.

Common Electronic Components Affected by Heat

Modern vehicles contain numerous electronic systems that are particularly vulnerable to heat stress. Understanding which components are most at risk helps illustrate why heat protection is so important.

Dashboard and Infotainment Systems

Dashboard electronics bear the brunt of solar heat gain because they sit directly in the sun’s path. LCD screens, touch sensors, and processing units all suffer when exposed to excessive temperatures.

LCD displays are particularly sensitive to heat. High temperatures can cause liquid crystal alignment problems that result in dead pixels, color shifts, or complete display failure. These screens often cost thousands of dollars to replace.

Touch screen sensitivity also degrades with heat exposure. The capacitive sensors that detect finger touch become less responsive as temperatures rise, making the interface frustrating or unusable.

Navigation and GPS Units

GPS and navigation systems contain sensitive radio receivers and processors that can malfunction when overheated. These systems often shut down automatically when internal temperatures exceed safe limits.

The GPS receiver chips are particularly vulnerable because they must process extremely weak satellite signals. Heat-induced electrical noise can interfere with signal reception, causing location errors or complete signal loss.

Internal batteries in GPS units also degrade rapidly when exposed to high temperatures. These batteries may swell, leak, or completely fail when subjected to the extreme heat of unprotected vehicle interiors.

How Excessive Heat Damages Vehicle Electronics

The mechanisms of heat damage in electronics are well understood and predictable. Knowing how heat causes damage helps explain why prevention through window tinting is so effective.

Temperature Thresholds for Electronic Failure

Most automotive electronics are designed to operate safely up to about 85°C (185°F). However, many components begin experiencing reduced performance and accelerated aging at much lower temperatures.

Consumer electronics like smartphones and tablets typically shut down at internal temperatures around 70°C (158°F). Vehicle interiors can easily exceed these temperatures on hot days, creating conditions that stress or damage electronic components.

Window tinting near me professionals understand that even moderate temperature reductions can keep electronics within their optimal operating range. A 15-degree reduction might mean the difference between normal operation and thermal shutdown.

Thermal Cycling and Component Degradation

Repeated heating and cooling cycles cause more damage than constant moderate temperatures. This thermal cycling creates mechanical stress that eventually leads to component failure.

Expansion and Contraction Effects

Different materials expand and contract at different rates when heated and cooled. This differential expansion creates mechanical stress at connection points and interfaces between different materials.

Circuit boards contain multiple materials – silicon chips, copper traces, plastic substrates, and metal connectors. Each material responds differently to temperature changes, creating stress that can crack solder joints or separate connections.

These micro-cracks may not cause immediate failure but create high-resistance connections that generate heat and eventually fail completely. The process is cumulative, with each thermal cycle adding more stress.

Solder Joint Failure Mechanisms

Solder joints are particularly vulnerable to thermal cycling because they must maintain electrical connections between materials with different expansion rates. The constant stress eventually causes the solder to crack or separate.

Modern lead-free solder is more brittle than traditional lead-based solder, making it even more susceptible to thermal cycling damage. These failures often manifest as intermittent problems that are difficult to diagnose.

Window tinting reduces the temperature extremes that cause thermal cycling damage, significantly extending the life of solder joints and electrical connections throughout your vehicle’s electronic systems.

The Role of Solar Heat Gain in Vehicle Interiors

Vehicle interiors act like greenhouses, trapping solar energy and creating temperatures far higher than outside air temperatures. This solar heat gain is the primary source of electronics-damaging heat.

Infrared Radiation and Heat Buildup

Sunlight contains three types of energy: visible light, ultraviolet radiation, and infrared radiation. Infrared radiation, though invisible, carries about 53% of the sun’s energy and is the primary cause of heat buildup in vehicles.

When infrared radiation passes through glass, it heats up interior surfaces. These heated surfaces then radiate heat throughout the cabin, creating the extreme temperatures that damage electronics. Dark surfaces like dashboards absorb more infrared energy and become particularly hot.

Quality window tinting blocks up to 95% of infrared radiation before it enters your vehicle. This dramatic reduction in heat-producing energy prevents the extreme temperatures that stress electronic components.

Greenhouse Effect in Enclosed Vehicles

Vehicle interiors experience an extreme greenhouse effect because the enclosed space traps heated air. Even with some ventilation, temperatures can rise 40-50 degrees above outside air temperature.

This greenhouse effect is particularly problematic for parked vehicles where there’s no air circulation. Electronics continue operating even when the engine is off, using small amounts of power to maintain memory settings and standby functions.

The combination of no air circulation and continued electronic operation creates perfect conditions for heat damage. Components that might survive high temperatures for short periods suffer damage when exposed to sustained heat without cooling.

Window Tinting Technology for Heat Reduction

Modern window tinting technology specifically targets the heat-producing wavelengths of sunlight while maintaining visibility and electronic transparency.

Infrared Rejection Properties

Advanced window tint films use sophisticated materials to reject infrared radiation without blocking visible light. This selective filtering provides heat protection while maintaining the visibility needed for safe driving.

Ceramic tint films excel at infrared rejection, blocking up to 95% of heat-producing radiation. These films use nano-ceramic particles that vibrate at infrared frequencies, converting the energy to harmless motion rather than allowing it to pass through as heat.

Carbon tint films also provide excellent infrared rejection through absorption rather than reflection. The carbon particles absorb infrared energy and dissipate it through the film material rather than allowing it to enter the vehicle interior.

Selective Wavelength Filtering

The most effective window tint for electronics protection don’t simply darken all light – they selectively filter specific wavelengths that cause heat buildup while allowing useful light to pass through.

Ceramic Tint Heat Performance

Ceramic tint represent the premium solution for electronics protection because they target heat-producing infrared radiation specifically. They can reject 95% of infrared energy while allowing 70% or more of visible light to pass through.

This selective filtering means you get maximum heat protection without compromising visibility. The result is a cooler interior that protects electronics while maintaining the light levels needed for safe driving.

Ceramic films also don’t interfere with electronic signals, ensuring that GPS, cellular, and radio systems continue operating normally. This signal transparency is crucial for modern vehicles with extensive electronic systems.

Carbon Tint Thermal Properties

Carbon tint films provide excellent heat absorption properties that complement their infrared blocking capabilities. The carbon particles absorb heat energy and distribute it across the film surface where it can be dissipated.

This heat absorption creates a cooling effect that goes beyond simple infrared blocking. The film actively removes heat energy from the system rather than just preventing its entry.

Carbon tint also provide consistent performance across all wavelengths, offering broad-spectrum heat reduction that protects electronics from all types of heat-producing solar radiation.

Specific Electronics Protected by Window Tinting

Different vehicle electronic systems benefit from heat protection in specific ways. Understanding these benefits helps illustrate the comprehensive value of quality window tinting.

Advanced Driver Assistance Systems (ADAS)

Modern ADAS systems rely on cameras, sensors, and processors that are extremely sensitive to temperature variations. These systems must operate within tight tolerances to provide accurate safety functions.

Camera sensors can suffer permanent damage from excessive heat, developing dead pixels or color shifts that compromise their ability to detect obstacles, lane markers, or traffic signs. These cameras often cost several thousand dollars to replace.

Radar and lidar sensors also contain sensitive electronics that can drift out of calibration when exposed to extreme temperatures. This drift can cause false alarms or, worse, failure to detect actual hazards.

Entertainment and Communication Systems

Infotainment systems represent some of the most expensive and heat-sensitive electronics in modern vehicles. These systems combine multiple functions that all suffer from heat exposure.

Hard drives in entertainment systems are particularly vulnerable to heat damage. The lubricants that allow smooth operation break down at high temperatures, causing mechanical failure that requires complete system replacement.

Bluetooth and Wi-Fi modules can suffer range and connection quality degradation when overheated. These modules often share circuit boards with other components, so failure can affect multiple system functions.

Climate Control Electronics

Ironically, the electronic systems that control your vehicle’s climate are themselves vulnerable to heat damage. These systems must operate reliably in all conditions to maintain cabin comfort.

Sensor Protection and Calibration

Temperature and humidity sensors must maintain accurate calibration to provide proper climate control. Heat exposure can cause sensor drift that results in incorrect temperature readings and poor climate control performance.

Air quality sensors are particularly sensitive because they rely on chemical reactions that are temperature-dependent. Heat can alter these reactions, causing false readings or sensor failure.

Window tinting Montrose, CO installations help protect these sensors by maintaining more stable interior temperatures that allow accurate sensor operation.

Electronic Control Unit Longevity

Climate control ECUs contain multiple processors and memory chips that are vulnerable to heat stress. These units often operate continuously, making them particularly susceptible to thermal damage.

The constant operation combined with heat exposure accelerates component aging and increases the likelihood of memory corruption or processor failure. These failures often require complete ECU replacement.

Heat protection through window tinting extends ECU life by reducing operating temperatures and thermal cycling stress, saving thousands of dollars in potential repair costs.

Temperature Reduction Benefits of Quality Tinting

The temperature reduction achieved through quality window tinting provides measurable benefits for electronic component protection and longevity.

Measurable Interior Temperature Differences

Professional testing shows that quality window tinting can reduce interior temperatures by 15-20 degrees Fahrenheit compared to untinted vehicles. This reduction brings many electronic systems back into their optimal operating range.

Surface temperatures on dashboards and other interior components can be reduced by even greater amounts – sometimes 30-40 degrees. These surface temperature reductions directly benefit electronics mounted in or near these hot surfaces.

Speed and Tech Motoring has documented temperature reductions in real-world conditions that demonstrate the significant cooling effect of quality window tint installation.

Consistent Operating Environment Creation

Beyond absolute temperature reduction, window tinting creates more consistent interior temperatures that reduce thermal cycling stress. This consistency is often more important than absolute temperature levels for electronics protection.

Consistent temperatures allow electronic components to reach thermal equilibrium and operate within their designed parameters. This stability reduces stress and extends component life significantly.

The reduced temperature variation also helps maintain calibration in sensitive sensors and measurement devices that rely on stable operating conditions.

Long-term Cost Savings from Electronics Protection

The electronics protection provided by window tinting generates significant long-term cost savings that often exceed the initial tinting investment.

Preventing Premature Component Replacement

Modern vehicle electronics are expensive to replace, with some systems costing thousands of dollars. Protecting these systems from heat stress can extend their life significantly, avoiding premature replacement costs.

Infotainment systems, navigation units, and ADAS components represent particularly expensive replacement costs. These systems often cannot be repaired and must be replaced entirely when heat damage occurs.

The cost of quality window tinting is typically less than the cost of replacing a single major electronic component, making heat protection an economically sound investment.

Warranty Preservation Considerations

Many vehicle warranties exclude coverage for damage caused by “environmental factors,” which can include excessive heat exposure. Protecting electronics from heat stress helps ensure warranty coverage remains valid.

Some manufacturers specifically require proper ventilation and temperature control to maintain electronics warranties. Window tinting helps meet these requirements by reducing interior heat buildup.

Extended warranties on aftermarket electronics often have similar temperature-related exclusions. Heat protection through window tinting helps maintain coverage for these valuable additions.

Regional Climate Factors and Electronics Protection

Different climates create varying levels of electronics stress, with some regions requiring more aggressive heat protection strategies.

High-Altitude Heat Challenges

High-altitude locations face increased solar intensity that creates more severe heat buildup in vehicles. The thinner atmosphere provides less filtering of solar radiation, allowing more energy to reach vehicle interiors.

UV intensity increases by about 8-10% for every 1,000 feet of elevation, creating more severe conditions for electronics protection. This increased intensity makes quality window tinting even more important at altitude.

Temperature swings are also more extreme at altitude, creating greater thermal cycling stress that accelerates electronics aging.

Desert Climate Electronics Stress

Desert climates present extreme challenges with intense solar radiation, high ambient temperatures, and low humidity. These conditions create perfect storms for electronics damage.

The combination of direct solar heating and high ambient temperatures can push vehicle interiors well above the survival limits of many electronic components. Window tinting becomes essential rather than optional in these climates.

Low humidity also affects electronic components by allowing static electricity buildup and changing the electrical properties of some materials. Heat protection helps maintain more stable conditions overall.

Professional Installation for Maximum Protection

Professional installation ensures that window tinting provides maximum electronics protection through proper film selection and application techniques.

Quality Film Selection for Heat Rejection

Different window tint films provide varying levels of heat rejection and electronics protection. Professional installers understand which films provide the best protection for specific applications and climates.

Premium ceramic films offer the best heat rejection but require proper installation to achieve maximum performance. Professional installers have the experience and tools needed to achieve optimal results.

Film thickness, adhesive systems, and manufacturing quality all affect long-term heat rejection performance. Professional installation ensures these factors work together for maximum electronics protection.

Proper Installation Techniques

Installation quality directly affects heat rejection performance. Bubbles, gaps, or poor adhesion can create hot spots that compromise electronics protection.

Professional installers use controlled environments and specialized tools to ensure perfect film application. This attention to detail is crucial for achieving maximum heat rejection and electronics protection.

Proper edge sealing and trimming also affect long-term performance. Professional techniques ensure the film continues providing heat protection throughout its service life.

Premium Auto Solutions Serving the Olathe Community and Beyond in Montrose, CO

Premium Auto Solutions is dedicated to serving the diverse needs of the local community of Montrose, CO, including individuals residing in neighborhood like Olathe. With its convenient location near landmarks such as the Olathe high School and major intersections like Gunnison Rd & 6100 Rd and 6095 Rd & Guernsey Dr (coordinates: 38.56492129258407, -107.9394717708854), we offer window tinting near me services.

Get window tinting near me Services at Olathe Now

Navigate from Olathe to Premium Auto Solutions Now

The Role of Window Tinting in Preventing Heat Damage to Car Electronics

- Heat Rejection Efficiency:

- High-quality window tint block up to 80–90% of infrared radiation, the main source of heat inside cars.

- They also reject over 99% of harmful UV rays, protecting sensitive electronics and interior materials.

- Interior Temperature Reduction:

- Window tinting can lower cabin temperatures by 8 to 20°F (4.5 to 11°C) compared to untinted windows.

- This cooling effect reduces dashboard and electronic component temperatures that can exceed 160°F (71°C) on hot days.

- Impact on Electronics Longevity:

- Reduced heat exposure prevents overheating issues such as touchscreen lag, sensor errors, and premature wear of infotainment systems.

- UV protection helps avoid dashboard cracking, discoloration, and electronic casing brittleness.

- Additional Benefits:

- Lower cabin heat reduces air conditioning load, improving fuel efficiency and lowering emissions.

- Glare reduction enhances driver visibility and safety without compromising electronic signal reception

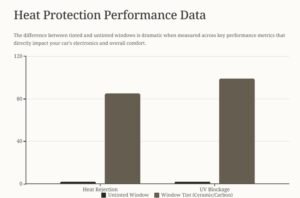

Visual Chart (suggested layout):

Metric Untinted Window Window Tint (Ceramic/Carbon) Infrared Heat Rejection (%) 0% 80–90% UV Ray Blockage (%) 0% >99% Interior Temperature Rise (°F) +40–50°F +20–30°F Dashboard Surface Temp (°F) ~160°F ~130°F or less

Sources: 5 StarAutoDetail (2024), ExtremeCleanMobileDetail (2025), GoWensAutomotive (2025)

Maintenance and Performance Optimization

Maintaining window tint in optimal condition ensures continued electronics protection throughout the film’s lifespan.

Seasonal Care for Maximum Effectiveness

Different seasons present varying challenges for window tint performance. Summer heat can stress the film material, while winter cold can affect flexibility and adhesion.

Regular cleaning with appropriate products maintains optical clarity and heat rejection performance. Dirty or damaged tint provides reduced protection for vehicle electronics.

Professional inspection and maintenance can identify developing problems before they compromise electronics protection. Early intervention often prevents more serious issues.

Signs of Tint Performance Degradation

Window tint performance degrades over time, reducing its ability to protect vehicle electronics from heat stress. Recognizing early warning signs helps maintain optimal protection.

Color changes, bubbling, or edge lifting indicate that the tint is losing effectiveness. These changes often coincide with reduced heat rejection performance that compromises electronics protection.

Increased interior temperatures or electronics malfunctions during hot weather may indicate that tint replacement is needed to restore full protection.

Window tinting provides essential protection for modern vehicle electronics by dramatically reducing interior heat buildup that can damage expensive and sophisticated systems. The technology specifically targets heat-producing infrared radiation while maintaining visibility and electronic signal transparency.

Professional installation ensures maximum protection through proper film selection and application techniques. The long-term cost savings from prevented electronics damage often far exceed the initial tinting investment, making heat protection through window tinting a smart financial decision.

Regular maintenance and performance monitoring ensure continued protection throughout the tint’s service life. The combination of initial quality installation and ongoing care creates a reliable protection system that preserves your vehicle’s valuable electronic systems for years to come.

Frequently Asked Questions

Can window tinting prevent all electronics damage from heat?

Window tinting significantly reduces heat-related electronics damage but cannot prevent all possible failures. It works best as part of a comprehensive protection strategy that includes proper ventilation and avoiding extended exposure to extreme conditions.

How much can window tinting reduce interior temperatures?

Quality window tinting can reduce interior temperatures by 15-20°F and surface temperatures by 30-40°F. These reductions are often sufficient to keep electronics within their safe operating ranges.

Does darker tint provide better electronics protection?

Not necessarily. Modern ceramic and carbon tint can provide excellent heat rejection even at legal tint levels. The film technology matters more than darkness for heat protection.

Will window tinting interfere with electronic systems?

Ceramic and carbon tint do not interfere with electronic signals. Metallic tint may cause some interference, but modern formulations minimize this issue for most applications.

How long does window tint maintain its heat rejection properties?

Quality window tint films maintain their heat rejection properties for 10-15 years or more with proper care. Premium ceramic films often outlast the vehicle itself while continuing to provide electronics protection.

Our Other Blog Posts Related Window Tinting

- How Window Tinting Saves Your Car’s Interior and Your Skin

- What Are the Benefits of Window Tinting in Montrose, CO?

- Window Tint Shades & Styles Montrose CO | Custom Vehicle Guide